Tooling is the very first stage of the production process. It is essential to choose the right mold manufacturer to achieve the desired product quality and efficiency. Our advanced tooling process promises you low-cost tooling and efficient production.

MIM Process

Metal Injection Molding | MIM

Feedstock

Fine metal powders are combined with binders to form the material to be used in production. The binder allows the metal powders to be held together and the material to be easily injected into the mold.

Molding

Molding is the process of injecting the feedstock into the mold cavity at a certain temperature under high pressure. The molding process allows parts to be shaped in a single step. The obtained part is called a “green” part, and it is about 20-25% larger than the final component to allow the shrinkage during the sintering.

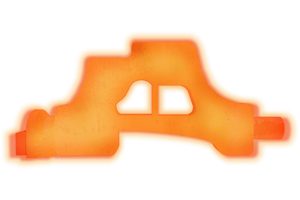

De-Binding

The “green” part is heated in a low-temperature furnace to remove most of the polymer binders, which are only required for the molding, and densify the powders in a controlled manner. After completing the process, the part is called the “brown” part, and it is ready for the final phase.

Sintering

The “brown” part is sintered by the diffusion method right below the melting temperature. The sintering phase allows metal particles to be densified. The process removes pores from the material, causing the part to shrink to 75-80% of its molded size. The shrinkage occurs uniformly and can be accurately predicted. The parts that complete the process are obtained as metal parts.

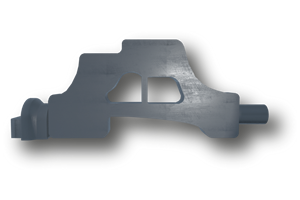

Metal Part

After completing the sintering process, the part achieves its final dimensions and final geometry, and it is ready for assembly. No secondary operations are required to improve tolerance or surface finish. However, components that need secondary operations, such as adding features, and improving material properties are processed at this stage.